The relationship between precision stamping and stamping

2024-08-23

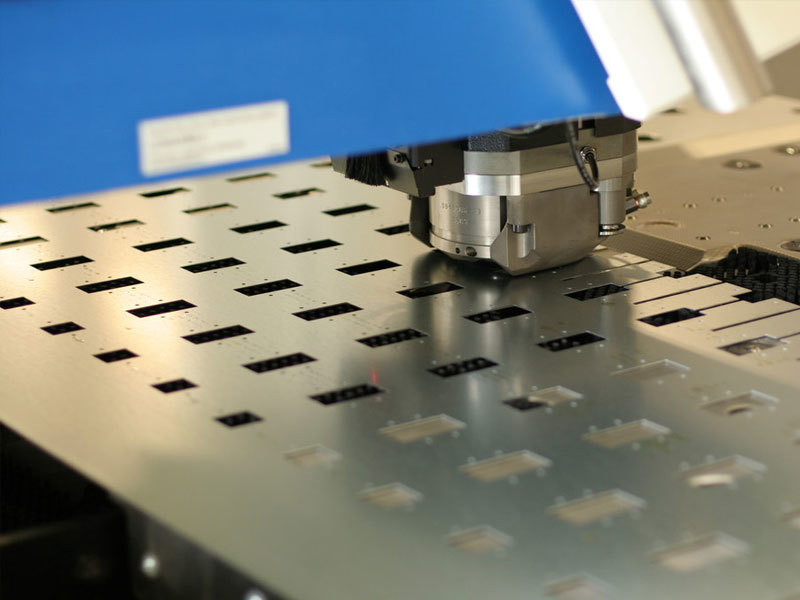

Precision stamping is an advanced form of stamping technology. It is developed on the basis of ordinary stamping process. By improving the guiding accuracy, reducing the gap between the male and female dies, increasing the reverse pressure and adopting the process measures such as the V-ring blank holder, it realizes the process of precision stamping or compounding with other forming processes, so as to obtain high-precision stamping parts.

The main difference between precision stamping and ordinary stamping is the different requirements for the accuracy of stamping parts. Precision stamping requires high precision of stamping parts, which is suitable for occasions that require high-precision stamping parts, such as auto parts, metal shells of electronic products, etc. Ordinary stamping has relatively low precision requirements for stamping parts, which is suitable for some products with low precision requirements, such as metal parts of some daily necessities.

The advantages of precision stamping are its high production efficiency, high quality stability, material saving and low cost. Because precision stamping uses molds to ensure the size and shape accuracy of stamping parts, and generally does not destroy the surface quality, the quality of stamping is stable and the interchangeability is good. In addition, precision stamping can process parts with large size range and complex shape, with high strength and rigidity. In contrast, although ordinary stamping can also meet some basic stamping needs, it may be slightly insufficient in terms of precision and complexity.

Key words:

Riveting solutions for large parts

Previous:

Next:

recommend News

Contact Us