How to maintain the laser cutting machine in summer?

2024-08-23

The temperature in summer is very high. Generally, no matter what kind of equipment we use, we need to be very careful, because summer is a high incidence area of accidents. Especially in the use of laser cutting machine when there are a lot of things to pay attention to, and in the maintenance of time, and not as simple as you think, so in the summer in the end should be how to use the maintenance of laser cutting machine:

In May, most cities in China began to heat up and entered the summer. The rise in residential electricity consumption is bound to have an impact on industrial electricity consumption. In many areas, the frequency of power outages is also increasing. And how to ensure that the industrial and mining enterprises laser cutting machine in the summer power switch during the high temperature period to normal use and maintenance work:

First of all, the focus is on users to buy laser cutting machines and understand the functions of the CNC system. Now on the market a lot of the so-called independent research and development system of enterprises, its CNC system function is not perfect. The numerical control system produced by our company has been tested in the market for decades, and the system is constantly upgraded. All aspects of performance are very good, all aspects of the design from the user's interest! The power protection function is a very practical function in the system. The factory encountered a power failure when using our laser cutting machine. The laser cutting machine can save the cutting graphics intact, and can cut directly at the cutting place when it is powered on. This effectively saves the plate and energy, does not need to repeat cutting, improves the efficiency for enterprise users, and reduces the cost.

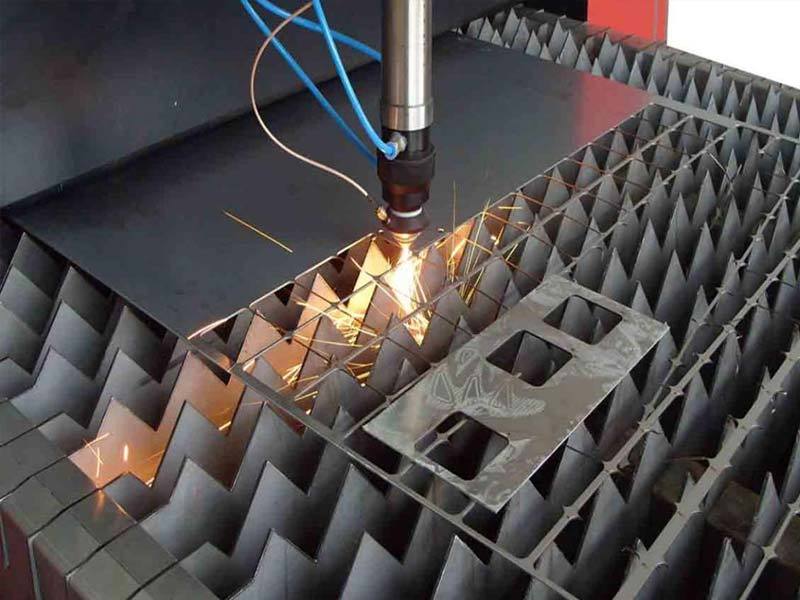

Since the laser cutting machine equipment is mainly used for thin plate cutting, the cutting method mainly uses plasma cutting. In the previous relevant documents, we have some descriptions according to the conditions of various pollution hazards plasma cutting methods. From the perspective of the operator, the use of laser cutting machines to reduce pollution caused by the use of equipment and harm to human health should be viewed from the following aspects of operation details.

1. laser cutting machine arc burn

Although the cutting thickness of the desktop CNC cutting machine is not very large, and the relative plasma power supply is mainly small and medium-sized power supply, but in the actual processing and production, there are still inevitable arc combustion damage, improper protection can also lead to electro-optic ophthalmia. Therefore, corresponding protective measures must be taken according to different operation methods. If you focus on the sun shading equipment of the table oxygen plasma cutting, the operator needs to wear goggles, and the color can be selected according to each person's vision.

2. to prevent hot metal or arc burns in normal operation

The skin should not be directly exposed to arc light to prevent arc burn. In addition, when air plasma cutting is performed, high-temperature slag or molten metal sputtering may be formed within a certain cutting range. These high-temperature substances will not only burn the skin, but may also cause accidents such as burns. Therefore, when operating the fiber laser cutting machine, pay attention to the distance between the operator and the equipment, and it is recommended that non-operators do not enter the equipment operating area. In addition, it is strictly forbidden to contact slits, strips or wires under high temperature during operation.

Key words:

Riveting solutions for large parts

Next:

recommend News

Contact Us